Case Study

GE Aerospace introduces automation to meet customer demand

0M+

saved within one year

0

robots deployed

Increasing productivity and scalability at GE Aerospace

At GE Aerospace (previously GE Aviation), the Asheville plant was looking for a way to increase productivity and scalability. To hit the numbers needed for their customers, GE Aerospace needed dramatic rate increases.

The solution was to automate their process, relieving the highly skilled operators from having to move the material around the plant. Automation resulted in $1.3M in savings in 2019 for GE Aerospace.

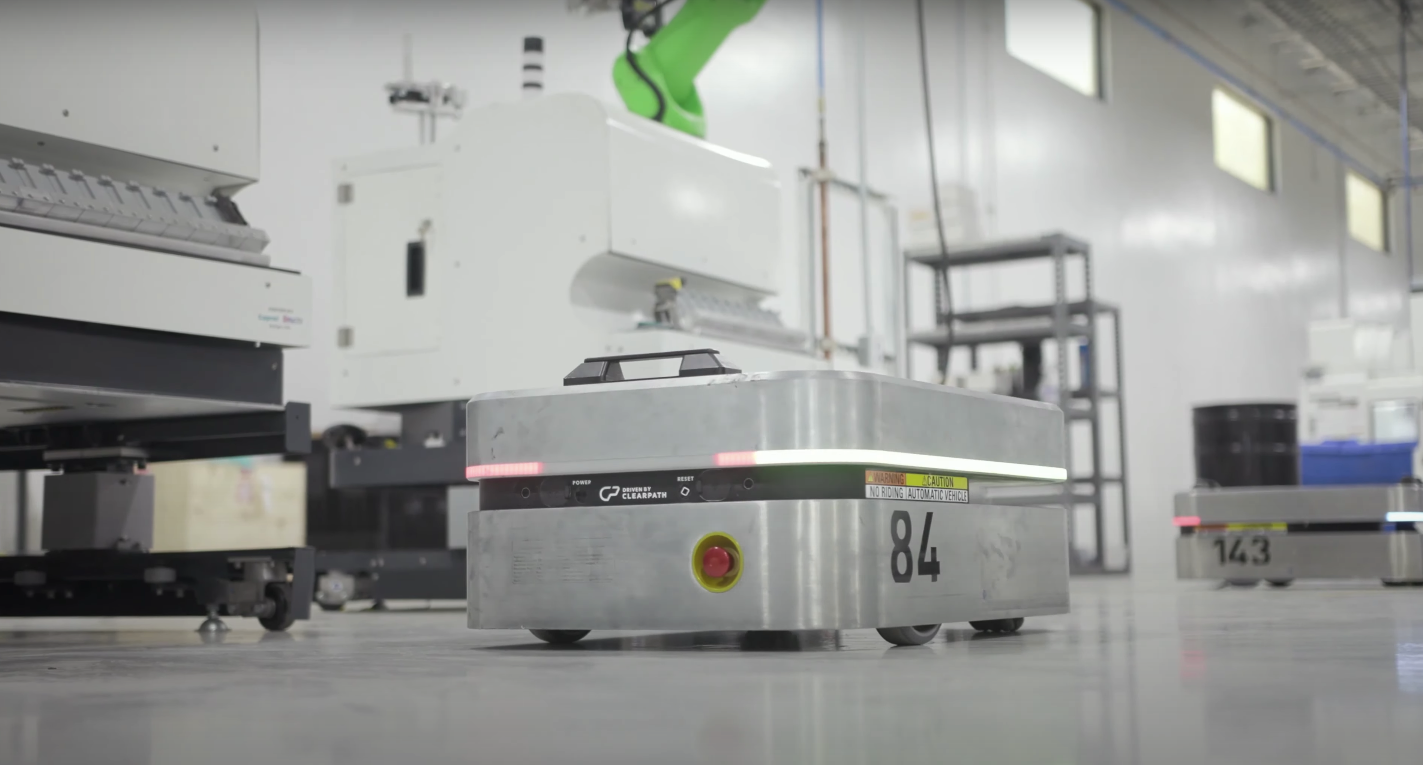

Watch OTTO 100 in this lean manufacturing environment.

OTTO 100 at GE Aerospace.

01/02