Blog

Are robots the answer to manufacturing hiring challenges?

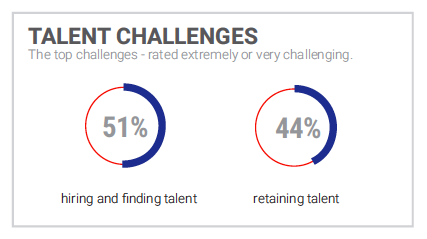

Regardless of industry or geography, manufacturers face daily struggles to meet their timelines because there are not enough workers to work on the line or the loading dock. For the fourth year, hiring and retaining qualified workers was listed as a top supply chain challenge in the 2022 MHI Annual Industry Report. 54% of respondents in the report listed hiring and retaining qualified workers as extremely or very challenging.

2022 MHI Annual Industry Report - Top talent challenges.

What factors are driving the labor shortage?

There have always been numerous challenges for manufacturers when it comes to hiring and retaining employees. Even before the pandemic, manufacturers were losing experienced employees as they entered retirement. During the pandemic, furloughed and laid-off employees were forced to find other jobs and are no longer in the market for manufacturing roles.

Today, these hiring and retention challenges are being exacerbated by an unprecedented tight labor shortage and the ongoing effects of the COVID-19 pandemic. Workers are calling in sick due to having COVID-19 or caring for a family member with it. In January, the Wall Street Journal reported that over 8 million American workers called in sick due to COVID-19.

These challenges lead to some shocking numbers. According to a recent Deloitte and The Manufacturing Institute report, US manufacturing companies are expected to have 2.1 million unfilled jobs by 2030. Another story from CNN reported that the impact of this labor shortage is expected to create a $1 trillion loss in the US economy in the same period.

Automation is the answer

From left, OTTO 1500, OTTO 100, OTTO 750, and OTTO Lifter.

Addressing the labor shortage means adopting new tools and processes, including using autonomous mobile robots (AMRs). While often portrayed as a threat to manufacturing jobs, AMRs have proven beneficial to manufacturers and workers.

A report from the International Federation of Robotics included several positive effects of automation on manufacturing jobs. According to the report, using robots has increased wages without reducing hours worked.

The jobs that robots fill include repetitive tasks like assembly, packaging, and rapid painting and welding. Needless to say, those are not the most desirable positions. But robots don't replace positions that require critical thinking and collaboration, which are often more rewarding.

Robotic Industry Association

Even more impressive, countries like Germany and Korea, with high use of robots, have some of the lowest unemployment rates. Lastly, the report also found that countries that invest in robots lost fewer manufacturing jobs than those that did not.

Put OTTO to work for you

Automation has been the answer for Story County, Iowa-based Danfoss Power Solutions. Their community was experiencing historically low unemployment, creating daily challenges for recruiting and retaining skilled workers. Danfoss implemented OTTO 1500 AMRs, which have helped scale their production without the need to hire workers.

OTTO 1500 at Danfoss Power Solutions.

Manufacturers can employ OTTO autonomous mobile robots to assist with multiple repetitive tasks in almost any environment. OTTO AMRs are designed to tackle straightforward tasks like automating push cart routes with the OTTO 100 to handling pallet transport loads up to 2,650 lb with the OTTO Lifter.

OTTO Lifter autonomously delivering materials.

OTTO is important to us because they're very reliable. They never call in sick and they do the job day in, day out. They allow us the flexibility to make our production facility function in the way that we need it to in order to achieve our future state; how we want our facility to look and how we want it to be optimized for material information flow.

Stephen Hines

Manufacturing Engineer, Danfoss Power Solutions

The next time you are reviewing resumes, add OTTO's to the top of the pile. OTTO has the experience and the references to show why it is your next great hire. See how quickly you can put OTTO to work in your facility today.