Blog

PACK EXPO Las Vegas 2023: Top insights for CPG manufacturers

Last week, 30,000 attendees from over 40 industries attended the most comprehensive packaging and processing trade show and conference of the year in Las Vegas, Nevada: PACK EXPO. Its 2,200 exhibitors showcased a variety of technologies and solutions that the consumer packaged goods (CPG) industry has been searching for, from bagging and wrapping devices to cartoning, filling and capping equipment.

OTTO Motors was on the show floor demonstrating our autonomous mobile robot (AMR) solution for CPG manufacturers worldwide. Alongside industry titan Berry Global, we also spoke on the show’s Innovation Stage about their business drivers to automate, why they chose AMRs specifically, how advanced automation will change the packaging industry, and more. You can watch the recorded presentation here.

Through this speaking session, our conversations with CPG manufacturers in our booth, walking the show floor, and sitting in on other sessions, the OTTO Motors team learned about many key market trends and insights at PACK EXPO Las Vegas 2023. Here are the top 3:

1. The CPG industry is facing many of the same challenges as other industries

Over the course of the show’s three days, our team heard countless manufacturers share their biggest driver for automation: labor shortages. With more than 2.4 million manufacturing jobs projected to go unfilled by 2028, the global labor shortage is top of mind for every industry. Manufacturers particularly mentioned how challenging it was to find labor for their dangerous, difficult, or undesirable jobs, including material handling.

Alongside shortages, manufacturers are also concerned about employee retention. In a Rockwell Automation session called “Empowering Your Workforce With Flexible Manufacturing,” the speaker asked his audience how many of them have seen a change in over 50% of their workforce in the last three years, and more than half of their hands raised. Challenges with labor retention and hiring is something we’ve seen across all industries, with our customers naming it as a top driver to automation, including Berry Global.

Image 1: Berry Global’s Director of Corporate Automation, Scott Spaeth (right), speaking alongside OTTO Motors’ CEO and Co-Founder, Matt Rendall (left), in a speaking session about “How AMRs are Shaping Berry Global’s Manufacturing Strategy.”

Similar to other industries, CPG manufacturers are also automating due to safety challenges, needed efficiency increases, and rising consumer demands. In a session from Addverb called “Warehouse Automation 2024 Trends and Innovation,” we learned that four out of five companies have more than 100 SKUs to meet this increasing need to adapt and offer more products. In fact, the CPG market is exploding, with an average of 30,000 new products launching each year. As a result of the simultaneous labor, safety, and efficiency challenges, manufacturers are turning to automation to increase their offering.

2. CPG manufacturers are evaluating AMRs and AGVs for their material handling needs

Automating material handling is an easy way to get started on your automation journey, and many CPG manufacturers are evaluating the available technologies. While a substantial number of conversations in our booth surrounded what the differences between an AMR and an automated guided vehicle (AGV) are, many CPG manufacturers also came to OTTO Motors to upgrade their existing AGV system.

While AGVs enable predictability for applications with fixed or limited interactions with the factory or other vehicles, AMRs deliver unmatched flexibility for dynamic, crowded facilities with changing workflows. The AMR market is continuing to grow as well, with renowned software, multiple form factors including flatbed and forked, and a wide range of payload capacities.

For example, at PACK EXPO Las Vegas 2023, OTTO Motors introduced the packaging industry to OTTO 1200, the highest performing heavy-duty AMR for compact spaces. Equipped with patented adaptive fieldset technology, OTTO 1200 quickly maneuvers around people and turns, delivering unmatched throughput with its best-in-class average speed.

3. CPG manufacturers want to see live demonstrations of exhibitor technologies

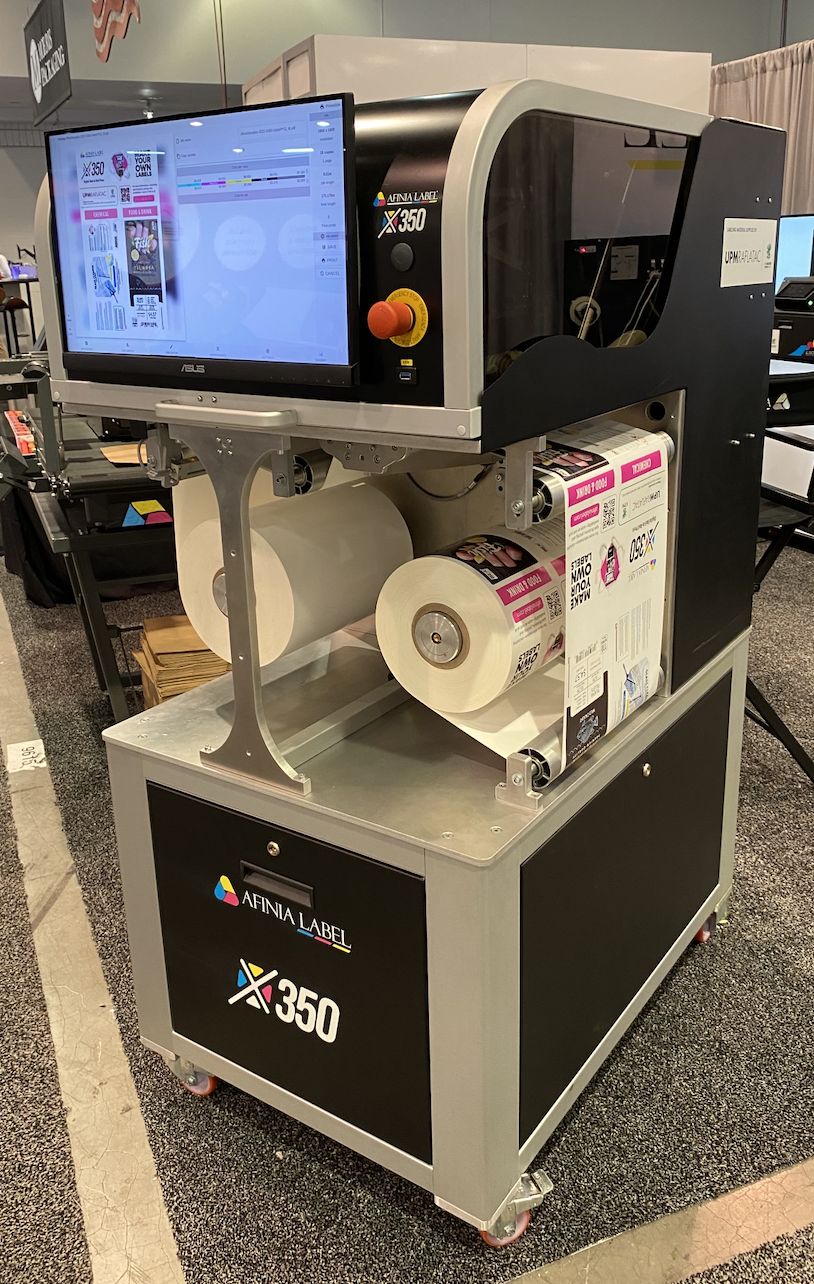

Across all three exhibitor halls, countless technologies were on display, doing real work. As the amount of available technologies grows, CPG manufacturers wanted to visualize the potential workflows for their facility as they walked past each booth. From robotic palletizers to automatic label printers, small and large booths alike displayed their solutions in action.

Image 2: Afinia Label showcasing their automatic label printer at PACK EXPO 2023.

Many PACK EXPO attendees stopped in their tracks to watch the demonstration at OTTO Motors’ booth. As one of the only exhibitors of mobile robot technology, countless manufacturers stopped to film our solution in action as they explored how automating material handling with OTTO AMRs can help improve operations at their global facilities. In the video below, check out a time-lapse of our demonstration near the end of the trade show.

The OTTO Motors team thoroughly enjoyed learning from conference sessions and attendees in our booth at PACK EXPO Las Vegas 2023. From the challenges faced to the solutions being considered, CPG manufacturers are well immersed in their automation journey and are excited to see the technologies in action. To learn more about our most recent AMR launch, register for the webinar on October 3rd from 1:00 - 1:45 p.m. EDT.