Blog

How becoming a showcase facility will benefit your bottom line

Warehouse managers who invest in innovative Industry 4.0 technology, such as automation, increase efficiency, reduce costs related to human error and adequately meet client needs. Automation can also help companies transition into innovative Showcase Facilities.

What is a showcase facility?

Showcase Facilities are innovative companies who adopt Industry 4.0 technologies such as automation, to become forward-thinking Factories of the Future. These Factories of the Future are positioned as industry leaders—leading to multiple bottom line benefits:

1. Automation helps meet customer demands

The 2019 MHI Annual Industry Report states customer demands for lower prices (56%) and faster response times (54%) are two of the top three challenges companies face.

Figure 1: The top three company challenges, as rated by the 2019 MHI Industry Report

Automation of material handling, in particular, allows workers to continue working at their stations, rather than spending time moving material around the factory floor. This improves efficiency and reduces waste which allows companies to complete products faster, and for cheaper, addressing both customer needs and benefiting your bottom line.

For example, the Chinese e-commerce company Alibaba realized adopting automation was crucial for meeting customer expectations. At its warehouse, 700 autonomous mobile robots carry and unload packages, resulting in a 50% higher order fulfillment rate than a traditional warehouse.

Alibaba’s use of automation also removes unnecessary human movement. Before the upgrade to autonomous mobile robots, Alibaba’s employees walked as many as 27,924 steps in a 7.5-hour shift. Through automation, employees have seen a 91% reduction in the amount they walk during a shift, allowing them to remain working on their area of expertise during their shifts.

2. Automation positions industry leaders

Use of autonomous vehicles will continue to rise in the manufacturing industry. While 4,000 robots worked in warehouses in 2018, that number will increase to more than 50,000 by 2025.

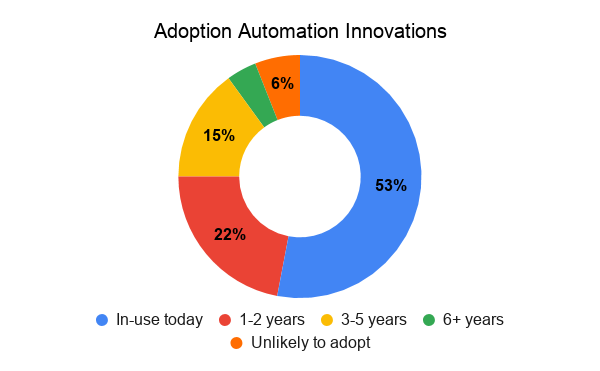

According to the MHI report, 53% of companies reported using at least one of these four technologies classified as automation, and another 37% are planning to implement these automation solutions over the next five years:

- 3D printing

- Robotics and automation

- Autonomous vehicles and drones

- Wearable and mobile technologies

Chart 1: Companies' estimation of when they will adopt automation innovations, including 53% who have automation in use in their facility today.

Through adopting innovative technologies such as automation, businesses can become industry leaders by providing faster and better service to customers, and standing out among their competitors. Innovative companies are able to grow their revenue by 38% over three years—nearly four times as quickly as companies that do not innovate.

Consumers often associate industry leadership with product quality and brand credibility. This association from being innovative results in more sales, which benefits the bottom line.

Leading companies are elevating their ‘supply chain digital consciousness’ to drive the kind of innovation that enables them to gain competitive advantage and thrive in today’s always-on economy.

George Prest

CEO, MHI

3. Digital technologies attract top talent

89% of manufacturers are having difficulty finding skilled workers; however, to combat this, more than 80% of companies report embracing digital technologies to attract new talent. The reduction in skilled workers is partly due to an aging workforce and a lack of interest by young workers in the manufacturing field. However, automation and robotics can help do the jobs impacted by the labor shortage, or attract youth to fill the positions.

We have a tremendous amount of robots; that’s ‘cool’ for students.

Tom Warner

CEO, ThyssenKrupp Presta Camshafts Danville

Becoming a Showcase Facility and implementing automation into a factory or warehouse, keeps workers from unnecessary, dull or repetitive tasks, such as material movement, and allows them to focus on more value-added tasks. Potential employees will view the company as an appealing place to work, helping the bottom line by making recruitment and hiring cheaper and faster.