Case Study

HIROTEC AMERICA aims for lights-out manufacturing with mobile manipulation solution

Advanced technologies drive corporate goal of lights-out operations

HIROTEC AMERICA provides weld assembly equipment for original equipment manufacturers (OEMs) including GM, Fiat Chrysler Automobiles, Ford, Toyota and BMW. For close to 30 years, the division has been a pivotal part of the global HIROTEC Group with more than $200 million of the $1.6 billion in worldwide sales. The company is built on the K2 philosophy of working towards continuous improvements (kaizen) and revolutionary changes in technology and process (kaikaku).

Working under the K2 philosophy, HIROTEC developed a corporate mandate to operate as a 24 hours, 7 days a week lights-out manufacturer. This revolutionary approach to operations would allow the company to reallocate spare parts operators into value-added tasks within the organization, improve productivity and achieve greater consistency by automating more aspects of production. The company decided to start with a mobile manipulation solution that was as flexible as human labor.

“HIROTEC is always looking for the next technology that is going to take over the industry,” says Gary Krus (VP of Business Development, HIROTEC AMERICA). “We started by looking for a platform that could make a dual-arm manipulator into a fully mobile manipulation solution.”

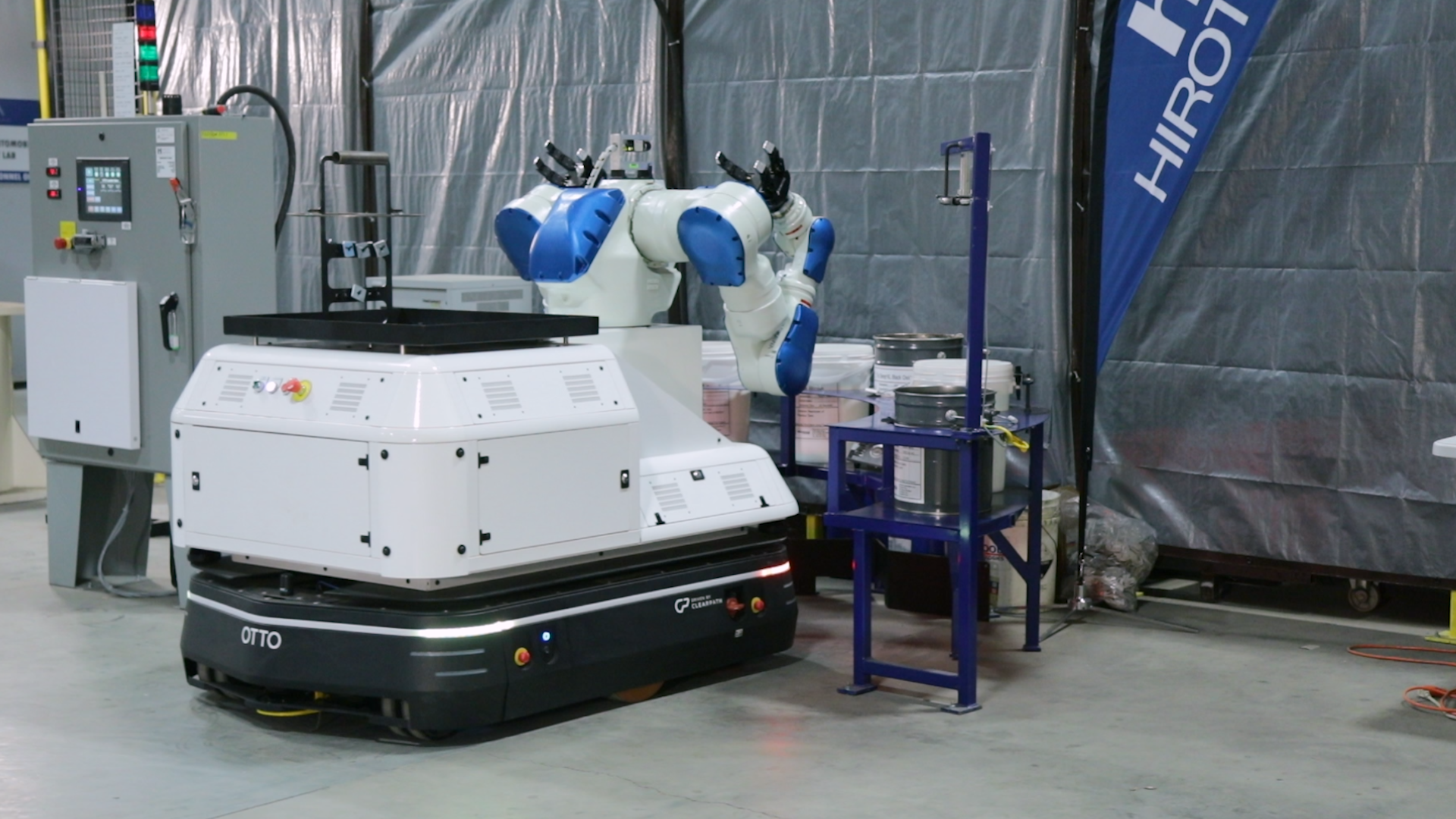

“By using the OTTO 1500 with the integrated Yaskawa Motoman, we have the technology to replicate human labor. OTTO lets us test and prepare future systems to meet our corporate goals of zero operators for spare parts.”

Kaikaku in action: Automating the black oxide process

One of the most inefficient processes in spare parts production is the black oxide process, which involves moving parts from bucket to bucket in a sequence with delays in between while the parts become oxidized. The final parts are coated in a thin corrosion-resistant surface, which must be consistent to ensure that the parts don’t rust.

This process was previously completed manually by operators who had to interrupt their task at the machine shop in order to transport parts to the process line and run them through the dipping procedure. The parts needed to be left in buckets for long periods of time, interrupting the flow of other processes around the facility as operators waited for the oxide line to be completed. Often the black oxide had to be repeated multiple times on the same parts – if operators did not dip them with perfect timing, they would come out inconsistently.

Gary and his team decided to automate the black oxide process first, due to the inefficiencies of performing this task manually.

OTTO was up and running around our facility within a day. In less than a week we had it running around between our different black oxide stations, and it’s providing much more consistent parts than what we saw with our manual process. We don’t have to run the parts through multiple times anymore, which improved our productivity in spare parts production.

Peter Mourelatos

R&D Project Engineer, HIROTEC AMERICA

Flexible automation with OTTO mobile manipulation

OTTO also provides the flexibility that HIROTEC needs in addition to completing processes reliably and consistently. “We didn’t have to change any of the infrastructure in our buildings to get OTTO to work. There's no hard-set paths that it has to follow like a traditional AGV, so it's much faster and easier to get OTTO up and running with new stations,” says Peter.

Rather than working behind a fence, OTTO can work in human-dense environments and travel safely around forklifts and human operators.

“Using OTTO is different than a typical industrial robot. We wanted to replace a human and do the job just the way a human does it manually. OTTO gives us the flexibility we needed,” says Gary.

“We’ve successfully implemented it at our site, and I can see OTTO being used by HIROTEC operations globally. It’s just the beginning for us as we work towards our goal of lights-out manufacturing with zero operators for spare parts production.”

OTTO 1500 with a Yaskawa Motoman arm.

01/02