Blog

What to ask your AMR vendor about scale before you buy

This is the third and final blog post in our series on scalability where our VP Product, Jay Judkowitz, shares valuable guidance on achieving scale with autonomous mobile robots (AMRs).

Now that you’ve seen all that OTTO does to create a scalable AMR solution and keep traffic flowing, here are some questions that we recommend you ask prospective AMR vendors to see if they rise to the same level when they tell you they can scale.

1. Deployment questions

- What is the largest production deployment your vendor has done before?

- On all axes of scale?

- Is it referenceable?

2. Traffic control questions

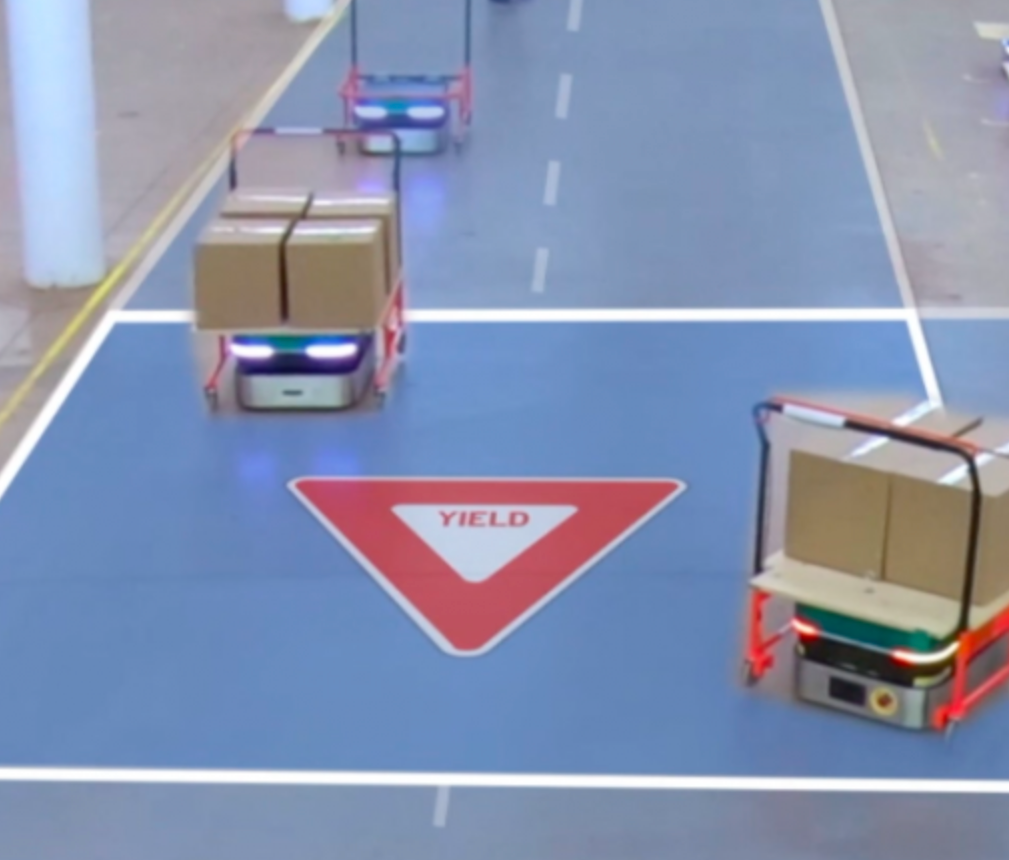

- Are the traffic rules configurable enough to maximize material flow for dozens of vehicles running jobs simultaneously while respecting the needs of human traffic throughput?

3. Performance questions

- Do the vehicles have ways to reroute to locations when there is a blockage on route?

- Can the vehicles pick from between equivalent destinations if the destination itself is blocked or offline?

- Can queues for payload transfer points and vehicle chargers be specified to fit with your existing facility constraints?

4. Reliability questions

Dig into reliability numbers because outages lower scale. Use the answers to these questions to calculate your required vehicles and make sure your quote is sufficient and that you won’t need to buy additional vehicles unexpectedly later on.

- Do they offer you MTBF for the robots?

- What is their MTTR between their support and your local partner?

- How frequently were mandatory action SW and HW bulletins published in the last year?

- How frequent are localization events or other required interventions?

5. Facility integration questions

How do they determine robot counts for your facility specifically? Again, you want to be sure that your quote is sufficient for your job throughput and not receive an unpleasant surprise later.

- Is it a spreadsheet that does a simple calculation based on the number of jobs needed, the time to execute jobs, and the time needed to charge?

- Do they simulate your actual environment - importing your map, creating a virtual fleet, and letting it run for days worth of cycles so that you find out precisely how the robots will behave over time taking into account bottlenecks that may build up over the course of a day based on your specific layout and their robots’ specific driving behavior?

I hope you have enjoyed this blog series on building a scalable AMR solution. I look forward to future robotics discussions!